Custom Steel Racks

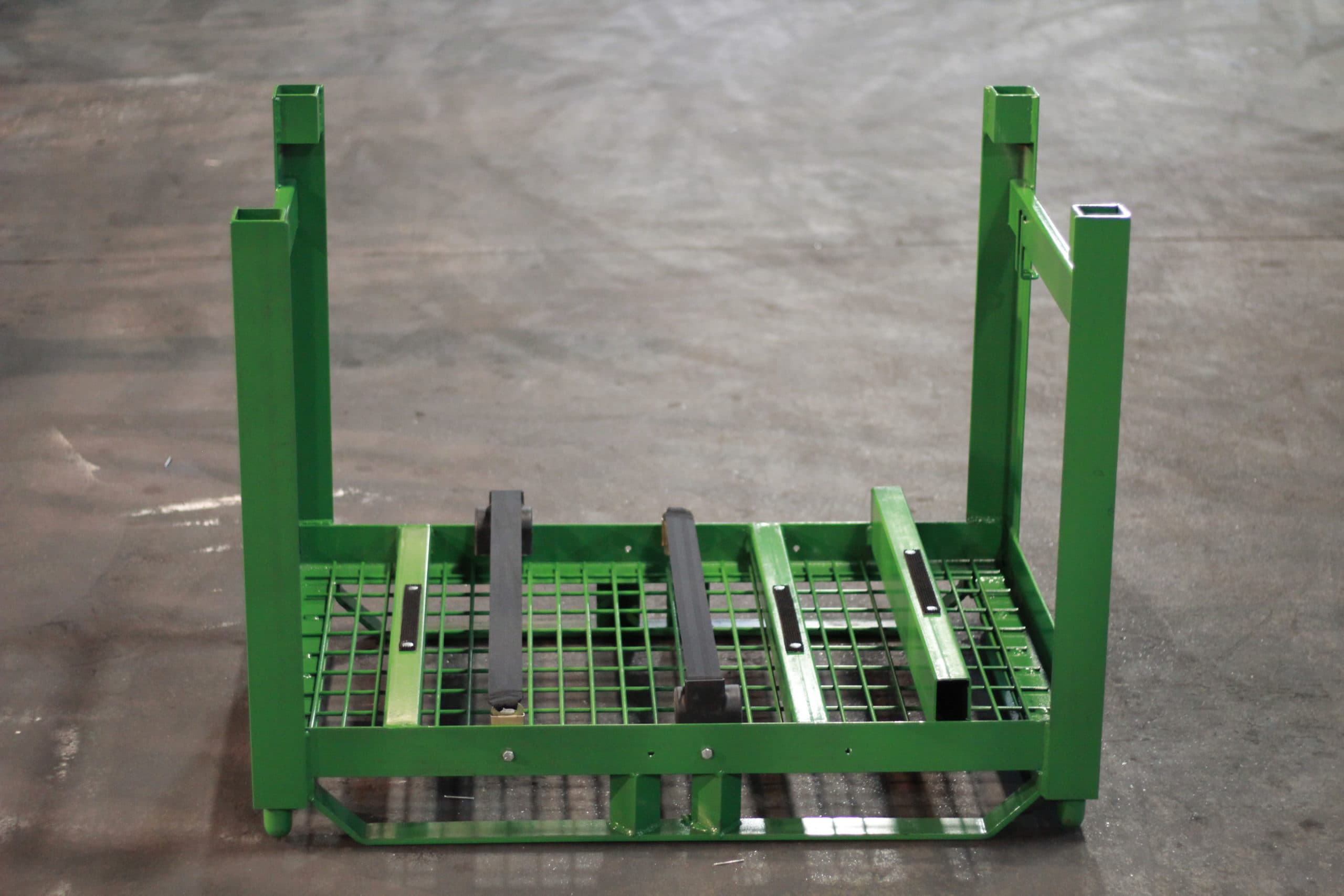

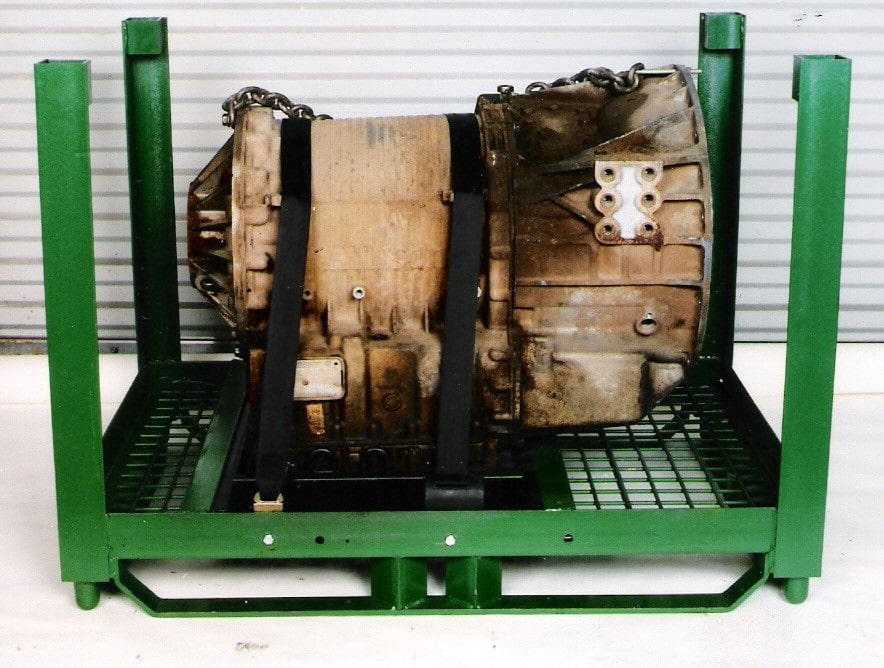

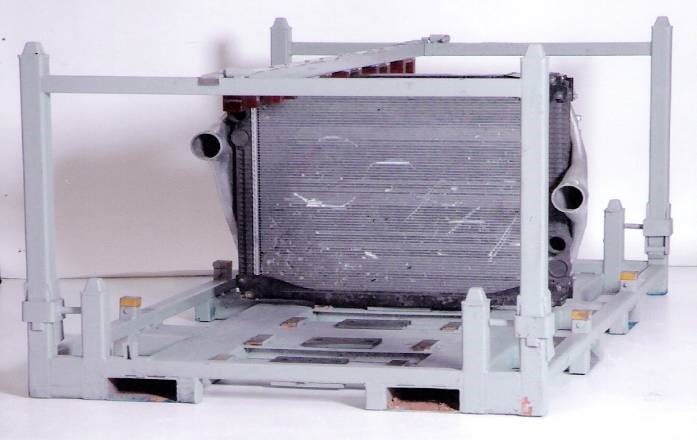

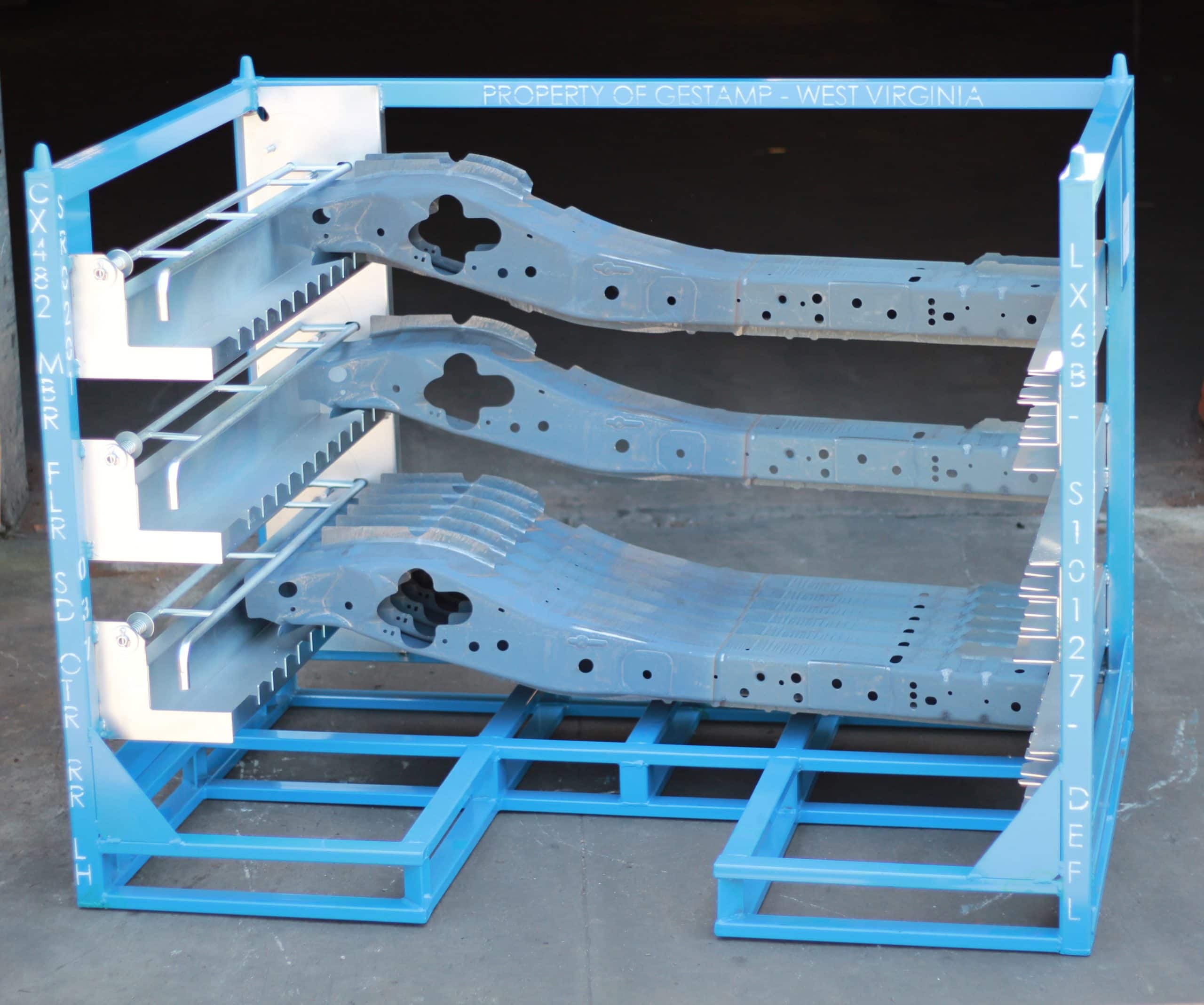

As a manufacturer with more than 30 years of experience in the fabrication of custom racks, our well-designed products provide an efficient and effective means of storing, protecting, and shipping a diverse range of components for the automotive industry. Engineered to transport goods ranging from heavy duty engine components to sensitive electronics, our material handling solutions are field-proven to enhance the productivity of various operations at every level of the supply chain.

Built from structural and stainless steel plate and tubing to within tight 1/16″ tolerances, each rack and packaging solution is designed to safely and securely transport components while protecting them from damage and handling errors. From robust, difficult to handle parts such as engines, transmissions, axles, and radiators, to fragile mirrors and sculpted components with Class A surfaces, our expertise has helped automakers streamline their vital manufacturing and assembly operations. We have created built-in features such as gas-assisted retractable shelving, pull-out shelving, stacking and nesting racks as well as those with cantilevered arms.

Our racks and packaging products are quality tested to ensure they meet the rigors of long-term daily use and meet the customer’s capacity requirements and desired efficiency standards. To learn more about our material handling solutions for automotive applications, contact us today.

Custom Fabrication of Steel Racks and Packaging Solutions Project Details

- Product Description

-

Custom shipping and storage racks for a multitude of automotive parts. Anything from sensitive parts or class A surfaces such as bumpers, fenders, mirrors, instrument panels and the like to robust, difficult to handle parts such as engines, transmissions, axles and radiators. As a manufacturer with 30 years’ experience in the fabrication of custom racks, we fabricate to allow for efficient and effective methods of storing, protecting and shipping to include solutions for returnable packaging. Our racks are built specifically to satisfy customer requirements, enhance manufacturing processes, improve warehouse efficiency and reduce shipping costs. Our products commonly prove cost effective by reducing damage in handling and eliminating costs associated with disposable packaging.

- Capabilities Applied/Processes

-

Primary:

Fabrication- Wire straightening and cutting

- Wire forming and bending

- Wire mesh fabrication per ASTM A185

- Hydraulic press bending and stamping

- Steel shearing and punching

- Mig or Arc welding per AWS D1.1 standards

- ISO 9001:2008 Certified Quality Management Systems

- Rack washing, painting & stenciling

- Rack finishing to include foam, urethane, bag and caster install

- Overall Part Dimensions

-

Our shipping and storage racks are custom and to customer specifications. Dimensions vary.

- Tightest Tolerances

-

Up to 1/16″

- Material Used

-

- Wire per ASTM A82 or ASTM A510

- Type 304 stainless steel wire

- Structural steel plates, angles, flats & channels per ASTM A36

- Hot rolled sheet per ASTM A1011

- Steel structural tubing per ASTM A500

- Filler metal per AWS A5.18/A5.18M

- Material Finish

-

- Hot dip galvanize per ASTM A123

- Zinc electroplating per ASTM B633

- Quick dry enamel paint

- Powder coating

- In Process Testing/Inspection Performed

-

QMS system certified to ISO 9001:2008

- Featured Industries

-

Automotive

- Product Types

-

- Transmission racks

- Dash/Instrument panel racks

- Radiator racks

- Engine racks

- Axle racks

- Steering wheel racks

- Seat frame racks

- Bumper, fender and fascia racks

- Window and door panel racks

- Mirror racks

- Tire racks

- Windshield racks

- Firewall racks

- Brake & brake line racks

- Delivery/Turnaround Time

-

In general, 4 to 6 weeks ARO for 1st articles, samples and prototypes & 8 to 10 weeks ARO and receipt of 1st article approval for production. Timeline may vary depending upon product, technical requirement and quantity.

- Delivery Location

-

Anywhere in US

- Standards Met

-

ISO 9001:2008

AWSD1.1 welder certified

- Rack Types

-

- Custom shipping racks

- Returnable or fold down racks

- Retractable shelf racks (using gas shocks)

- Pull out shelf racks (drawer type)

- Bag racks

- Nesting racks

- Stack racks

- WIP racks

- Cantilever arm racks