Custom Pallets, Steel Bins, & Wire Containers

Custom Pallets, Steel Bins & Wire Containers Project Details

- Product Description

-

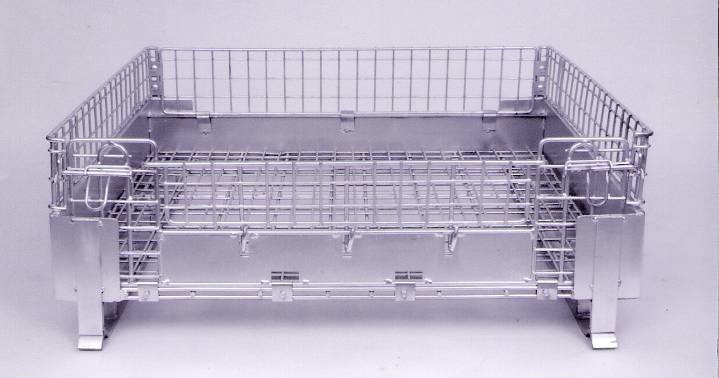

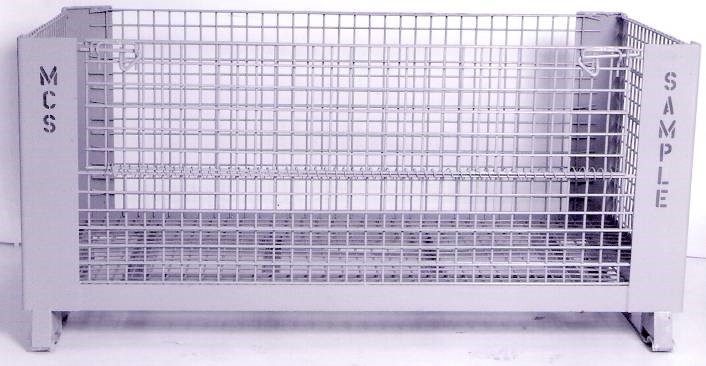

Custom pallets, corrugated bins and wire containers for various shipping, storing and warehousing applications. Generally speaking, our pallets are commonly made using a wire decking and structural steel base and foot for optimal strength. Our bins are commonly made from either or a combination of wire mesh and corrugated sheet, using structural angle as corner posts and a tubular base for underneath support. The combination of our expertise in welding wire mesh or panels and mig weld assembling per the AWS D1.1 standard, provides us the flexibility to fabricate as robust as necessary for your requirements. Our products are built specifically to satisfy customer requirements, enhance manufacturing processes, improve warehouse efficiency and reduce shipping costs. Pallets, bins and containers fabricated from steel provide a multitude of benefits to include optimal strength and durability, rapid content identification when stored, are non-flam-ability, easy and sturdy when stacking, ease of disposal (versus wood or plastic) and fold-ability if necessary. Various options to consider are overall size, capacity, desired opening (if using wire mesh), conveyor-ability, will products be shelved, folding or collapsing and finish. Many customers find our solutions cost effective by reducing damage in handling and eliminating costs associated with disposable packaging.

- Capabilities Applied/Processes

-

Primary:

Fabrication-

- Wire straightening and cutting

- Wire forming and bending

- Wire mesh fabrication per ASTM A185

- Hydraulic press bending and stamping

-

- Steel shearing and punching

- Mig or Arc welding per AWS D1.1 standards

- ISO 9001:2008 Certified Quality Management Systems

- Washing, painting & stenciling

- Overall Part Dimensions

-

Our pallets, steel bins and wire containers are custom and to customer specifications. Dimensions vary.

- Tightest Tolerances

-

Up to 1/16″

- Material Used

-

- Wire per ASTM A82 or ASTM A510

- Type 304 stainless steel wire

- Structural steel plates, angles, flats & channels per ASTM A36

- Hot rolled sheet per ASTM A1011

- Steel structural tubing per ASTM A500

- Filler metal per AWS A5.18/A5.18M

- Material Finish

-

- Hot dip galvanize per ASTM A123

- Zinc electroplating per ASTM B633

- Paint

- Powder coat

- In Process Testing/Inspection Performed

-

QMS system certified to ISO 9001:2008

- Featured Industries

-

Automotive

WarehousingDistribution

- Product Types

-

- Corrugated pallets

- Steel pallets

- Wire pallets

- Metal pallets

- Storage pallets

- Stainless steel bins

- Storage bins

- Metal bins

- Steel bins

- Corrugated bins

- Wire bins

- Shipping containers

- Steel containers

- Wire containers

- Stainless steel containers

- Corrugated containers

- Metal containers

- Storage containers

- Delivery/Turnaround Time

-

In general, 8 to 10 weeks ARO for 1st article & 8 to 10 weeks ARO and receipt of 1st article approval for production. Timeline may vary depending upon product, technical requirement and quantity.

- Delivery Location

-

Anywhere in US

- Standards Met

-

ISO 9001:2008

AWSD1.1 welder certified

Modular Container Solutions has established itself as a leading manufacturer of material handling products. Our technological capabilities in both the wire and steel arenas give us the flexibility to customize products to satisfy a diverse range of client needs. For optimal strength, our custom pallets, examples of which are pictured above, feature wire decking and a structural steel base. Our bins, also pictured, are typically constructed from a combination of wire mesh and corrugated sheet and feature structural angle as corner posts and a tubular base for underneath support. Unmatched expertise for welding wire mesh and panels according to the AWS D1.1 standard provides us with the flexibility to fabricate as robust a solution as your application requires, and we offer many high performance finishing options that withstand the rigors of repeated everyday use.

Built to specific customer requirements, tough steel construction provides optimal strength and durability, while the wire mesh allows rapid content identification. In addition to being non-flammable, our products are easily stacked, foldable, and reusable, helping eliminate the costs associated with disposable packaging. The versatility and inventiveness of our products enable clients to enhance their manufacturing and assembly processes, improve warehouse efficiency, and reduce shipping costs. contact us today to learn more.