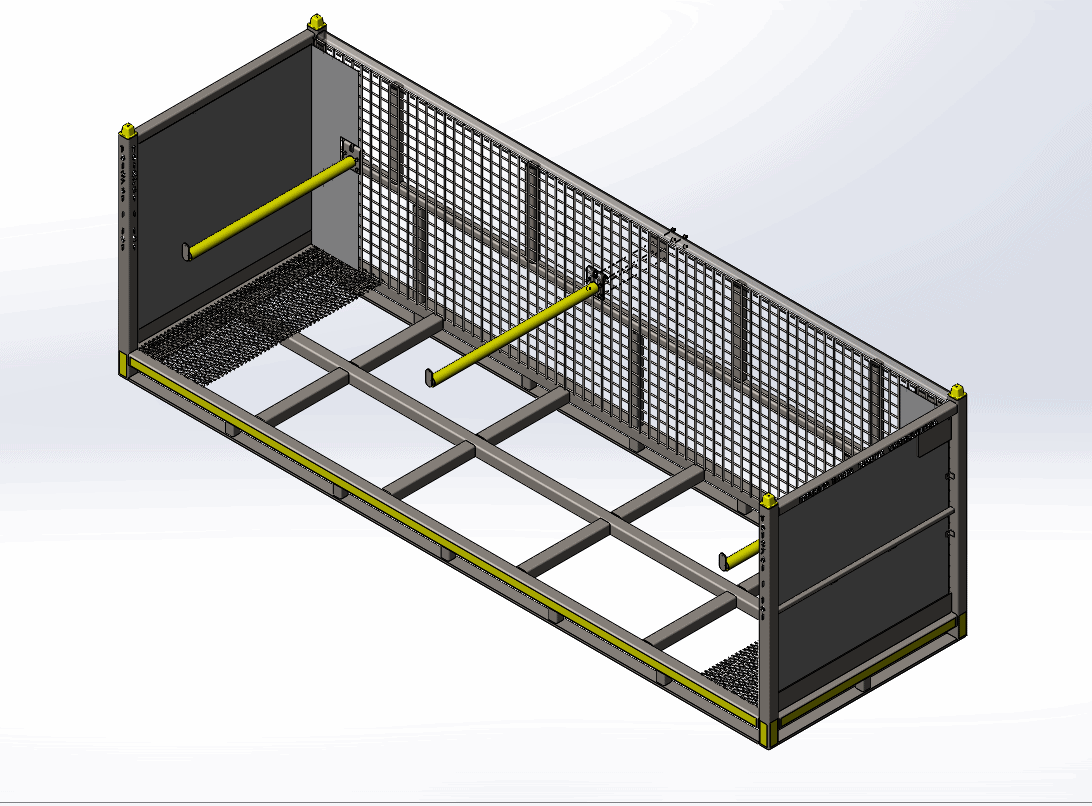

Retrofit, Refurbishing, & Repairs

Contracted by various automotive-industry customers looking to reduce the cost of replacing existing rack equipment, Modular Container Systems is a committed expert for rack rehabilitation. By using old assets to make new ones, we can help customers avoid the high cost of replacements while providing them the rack features and load capacity they need. We also provide rack repair, and can restore damaged racks to new condition.

We use a variety of fabrication processes to restore racks, including wire straightening and cutting, wire forming and bending, mesh fabrication, hydraulic pressing, steel shearing, welding, finishing, electroplating, and powder coating. Material used is Type 304 stainless wire, per ASTM A82 or A510 standards, along with structural steel plate per ASTM A36. Dimensional tolerances may be held as precise as ±1/16″.

Production turnarounds differ based on user requirements and features, but generally take 4-6 weeks to prototype and up to 8 weeks for final production approval. All fabrication is conducted within an ISO 9001:2008 certified facility.

To learn more about our custom mobile dollies, carts, and WIP Racks related work, see the table below and contact Modular Container Systems today.

Retrofit, Refurbishing and Repair of Racks Project Details

- Product Description

-

Especially since the significant increase in the price of steel in 2007, MCS has found great success in rendering old customer racks new through a retrofit or re-furbishing. The savings from salvaging the frame or structure of old racks has proven most economical and, generally speaking, far offsets the cost of “gutting” the racks internal contents to start new. From cutting old components and replacing them to secure new parts or models, to installing new foam or vacuum form trays, to re-painting and stenciling, customers have found great benefit in using old assets to make new ones.

In addition, we are well introduced in the repair of customer’s damaged racks. Before scrapping old racks or containers which could have plenty of use left only to replace them with new ones, consider the potential of making repairs to them and saving the required investment required in purchasing new.

- Capabilities Applied/Processes

-

Primary:

Fabrication-

- Wire straightening and cutting

- Wire forming and bending

- Wire mesh fabrication per ASTM A185

- Hydraulic press bending and stamping

- Steel shearing and punching

- MIG or Arc welding per AWS D1.1 standards

- ISO 9001:2008 Certified Quality Management Systems

- Rack washing, painting & stenciling

- Rack finishing to include foam, urethane, bag and caster install

- Electroplating

- Powder Coating

- Tightest Tolerances

-

Up to 1/16″

- Material Used

-

- Wire per ASTM A82 or ASTM A510

- Type 304 stainless steel wire

- Structural steel plates, angles, flats & channels per ASTM A36

- Hot rolled sheet per ASTM A1011

- Steel structural tubing per ASTM A500

- Filler metal per AWS A5.18/A5.18M

- Material Finish

-

- Hot dip galvanize per ASTM A123

- Zinc electroplating per ASTM B633

- Quick dry enamel paint

- Powder coating

- In Process Testing/Inspection Performed

-

QMS system certified to ISO 9001:2008

- Featured Industries

-

Automotive

- Product Applications

-

- Axle racks

- Bag racks

- Brake & brake line racks

- Bumper, fender and fascia racks

- Cantilever arm racks

- Custom shipping racks

- Dash/Instrument panel racks

- Engine racks

- Firewall racks

- Mirror racks

- Nesting racks

- Pull out shelf racks (drawer type)

- Radiator racks

- Retractable shelf racks (using gas shocks)

- Returnable or fold down racks

- Seat frame racks

- Stack racks

- Steering wheel racks

- Tire racks

- Transmission racks

- Window and door panel racks

- Windshield racks

- WIP racks

- Delivery/Turnaround Time

-

- 4 to 6 weeks ARO for 1st articles, samples and prototypes

- 8 to 10 weeks ARO and receipt of 1st article approval for production

- Delivery Location

-

Nationwide

- Standards Met

-

- Customer Specifications, 2D CAD Drawing

- ISO 9001:2008

- AWSD1.1 welder certified