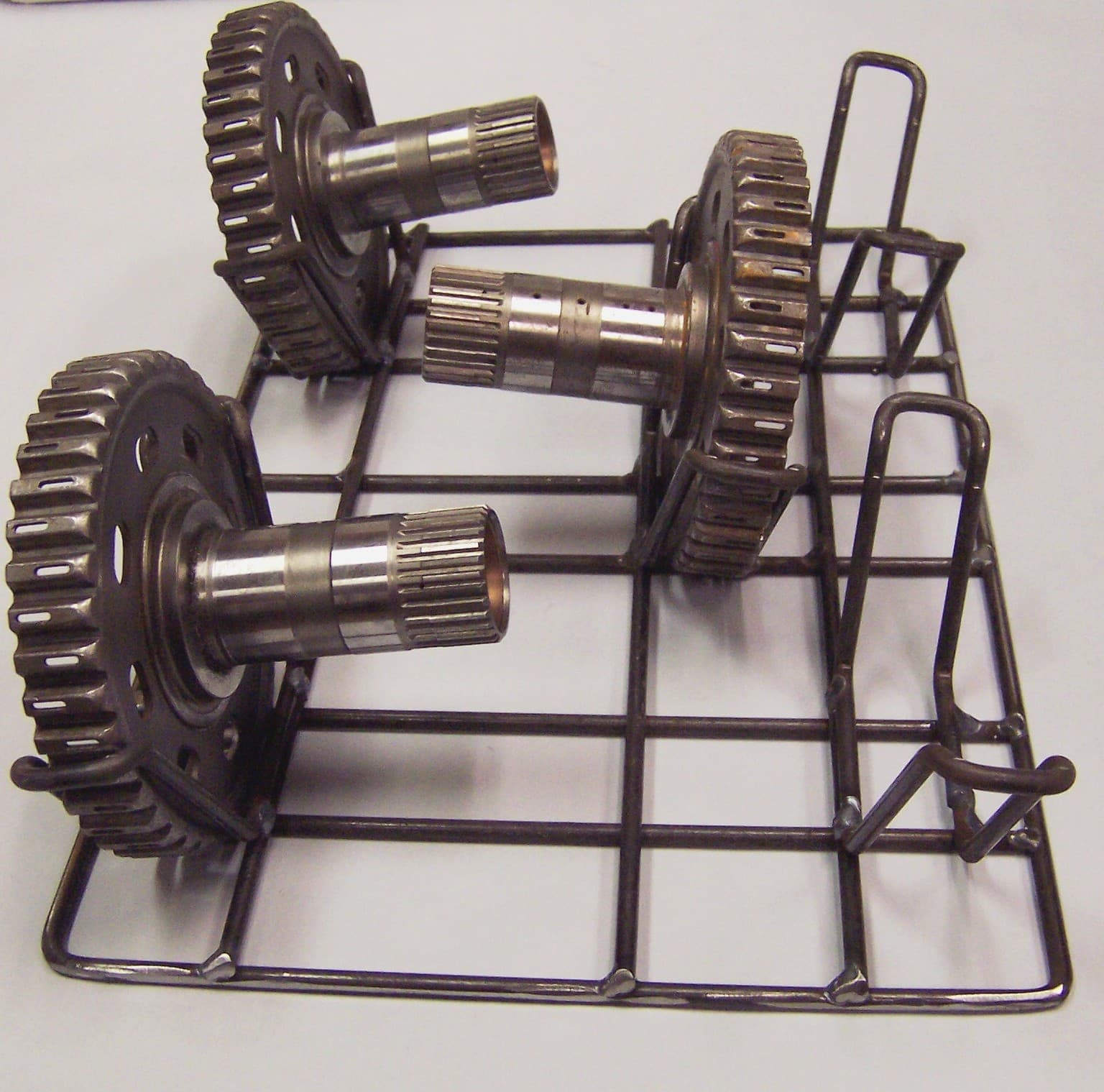

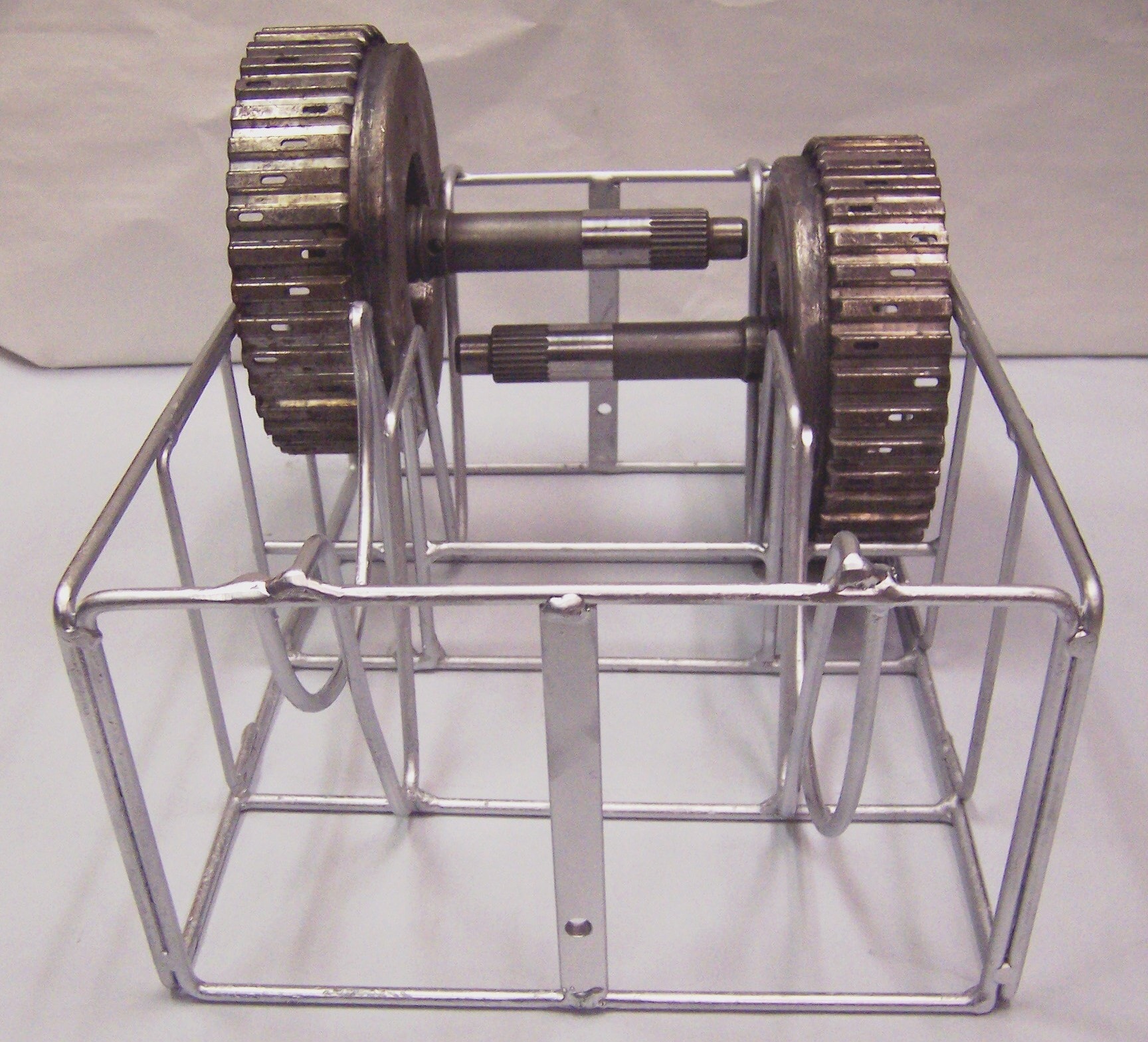

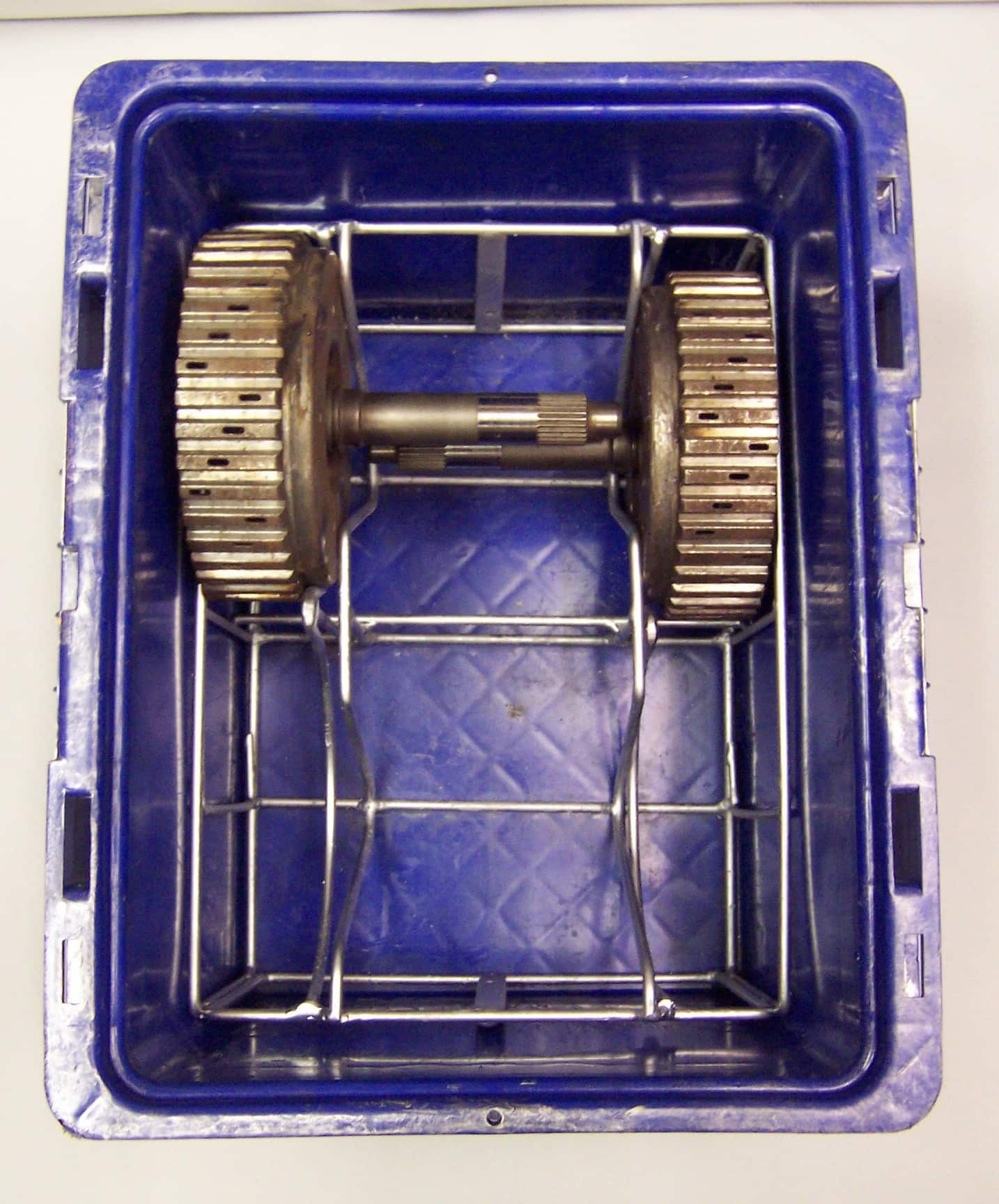

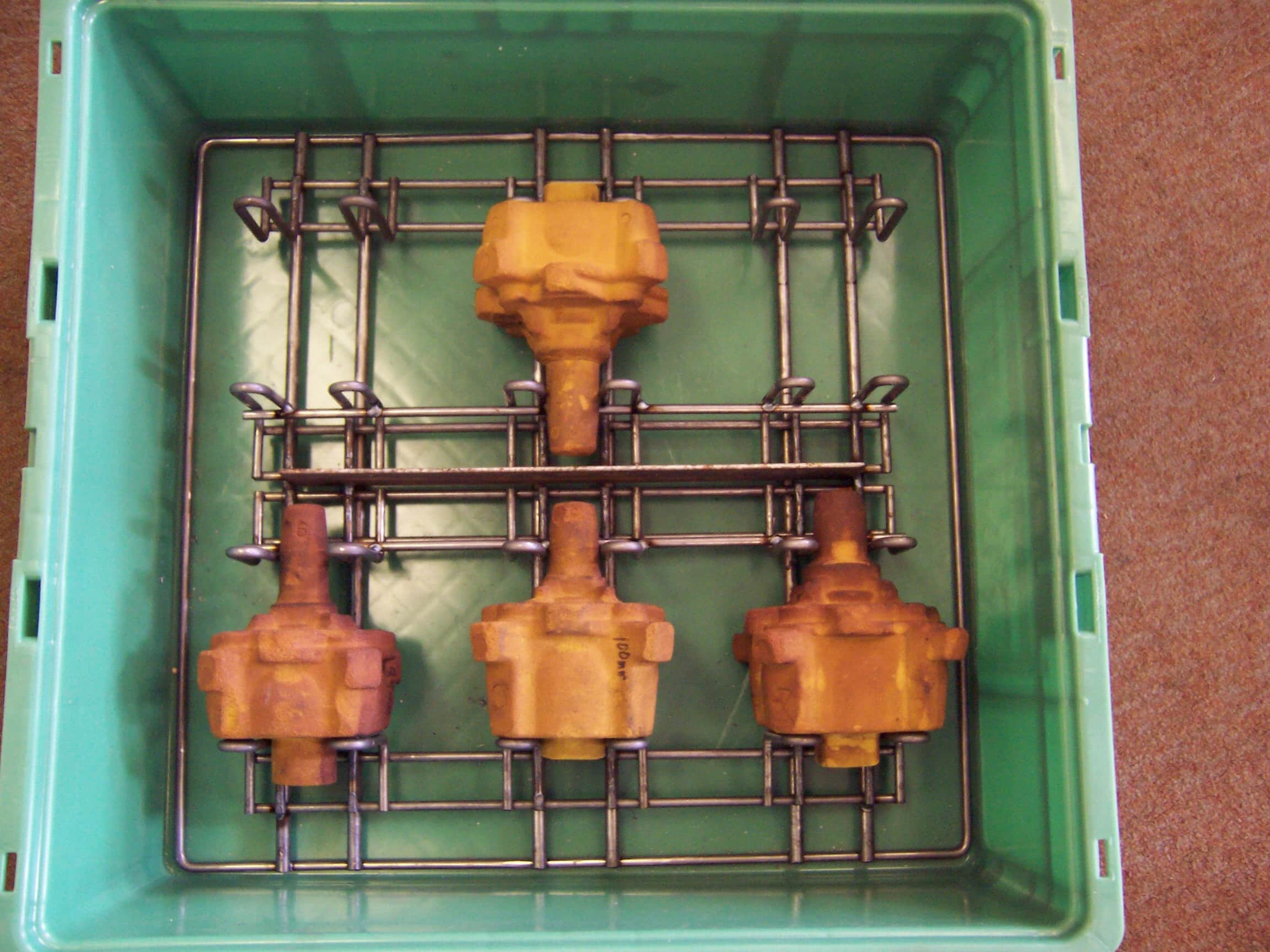

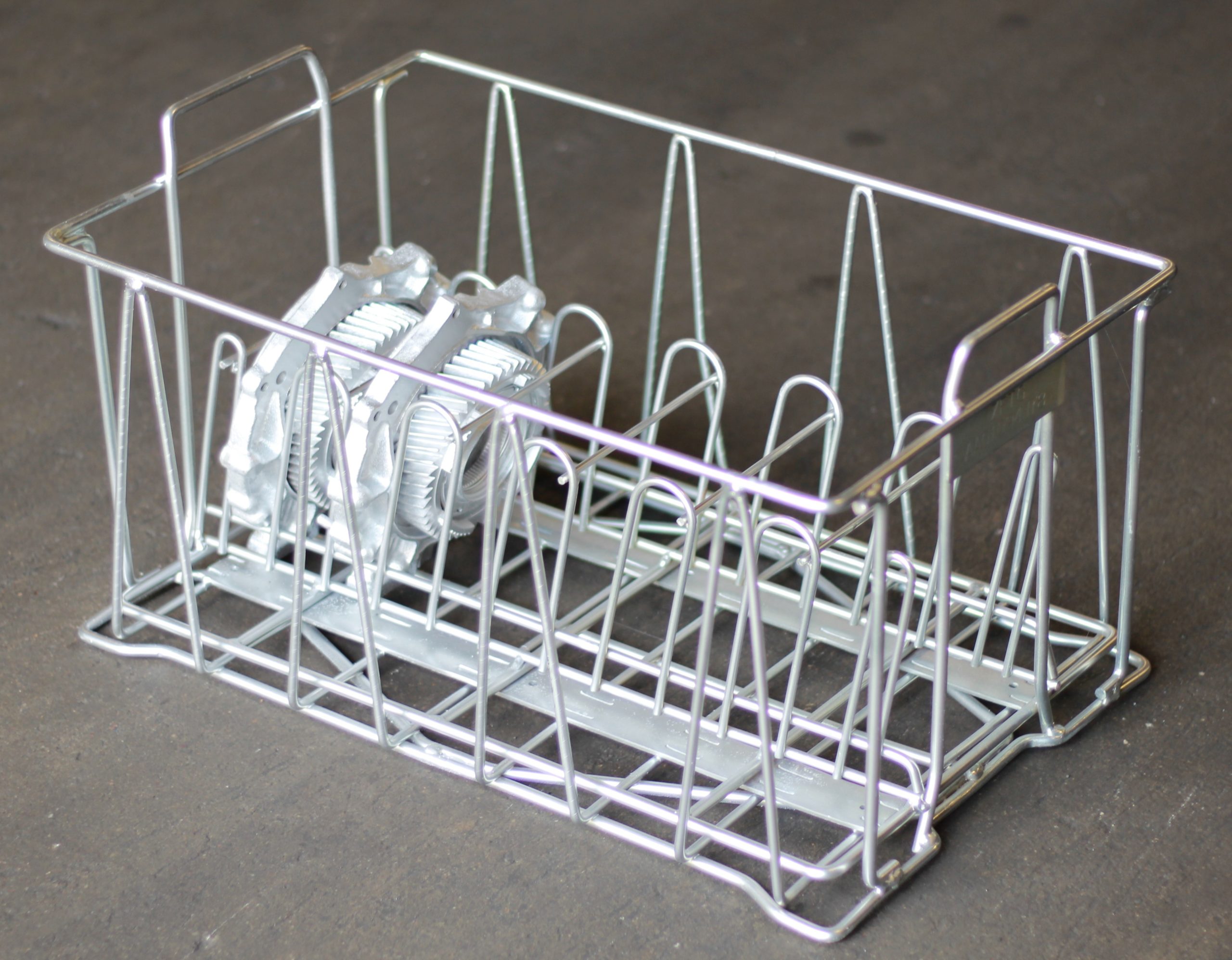

Wire Trays, Baskets, & Assemblies

Modular Container Systems, an expert in wire formed trays, baskets, and assemblies, has been repeatedly contracted by logistics, warehousing, and automotive customers to deliver custom handling systems. Through our customer-centric design and fabrication, we continue to deliver purpose built handling equipment that protects cargo and simplifies flow in shipping and handling applications.

Our wire trays, baskets, and assemblies are formed out of 304 stainless wire developed to ASTM A82 or A510 standards, and can be finished to have zinc electroplated, galvanized, enameled, E-coated, Plastisol, and Polyurea coatings. We fabricate using forming, bending, welding, and assembly processes, all occurring within an ISO 9001:2008 environment. Per customer requirements, these wire products may have dimensional tolerances as precise as ±1/16″, and may include features such as stackability, conveyor compatibility, and additional wire guards/holders.

To learn more about our wire container solutions, see the table below and contact Modular Container Systems today.

Wire Trays, Baskets and Assemblies Project Details

- Product Description

-

Fabrication of custom formed and welded wire products of all sizes and shapes. Our trays, baskets and assemblies serve a multitude of solutions from holding and securing parts in shipping, to in-process trays for degreasing & cleaning, to wire guards and holders for protecting sensitive items. Consider us experts in the manipulation and welding of wire. Depending upon product function, common finishes are electrolytic zinc, hot-dip galvanize, powder coat, e-coat, plastisol or polyurea.

- Capabilities Applied/Processes

-

Primary:

Fabrication-

- Wire straightening and cutting

- Wire forming and bending

- Wire mesh fabrication per ASTM A185

- Hydraulic press bending and stamping

- Mig or Arc welding per AWS D1.1 standards

- ISO 9001:2008 certified Quality Management System

- Finishes to include electrolytic zinc, hot-dip galvanize, powder coat, e-coat, plastisol or polyurea

- Overall Part Dimensions

-

Dimensions Vary

- Tightest Tolerances

-

Up to 1/16″

- Material Used

-

- Wire per ASTM A82 or ASTM A510

- Type 304 stainless steel wire

- Structural steel plates, angles, flats & channels per ASTM A36

- Hot rolled sheet per ASTM A1011

- Steel structural tubing per ASTM A500

- Filler metal per AWS A5.18/A5.18M

- Material Finish

-

- Hot dip galvanize per ASTM A123

- Zinc electroplating per ASTM B633

- E-coat

- Quick dry enamel paint

- Powder coating

- Plastisol

- Polyurea

- In Process Testing/Inspection Performed

-

QMS System Certified to ISO 9001:2008

- Featured Industries

-

- Automotive

- Warehousing

- Distribution

- Product Applications

-

- Baskets for automation

- Baskets for shipping and storing

- Cleaning baskets

- Conveyable baskets

- Degreasing baskets

- Expanded metal baskets

- Material handling baskets

- Perforated baskets

- Stackable baskets

- Stainless baskets, trays and assemblies

- Wash baskets

- Wire assemblies

- Wire baskets, trays and assemblies

- Wire forms

- Wire guards

- Wire hooks

- Wire inserts

- Wire mesh

- Wire mesh baskets

- Wire trays

- Delivery/Turnaround Time

-

- 4 to 6 weeks ARO for 1st articles, samples and prototypes

- 8 to 10 weeks ARO and receipt of 1st article approval for production

- Timeline may vary depending upon product, technical requirement and quantity

- Delivery Location

-

Nationwide

- Standards Met

-

- Customer Specifications, 2D CAD Drawing

- ISO 9001:2008

- AWSD1.1 welder certified

- Wire mesh fabrication per ASTM A185